"Slide-pressure-seal" connection

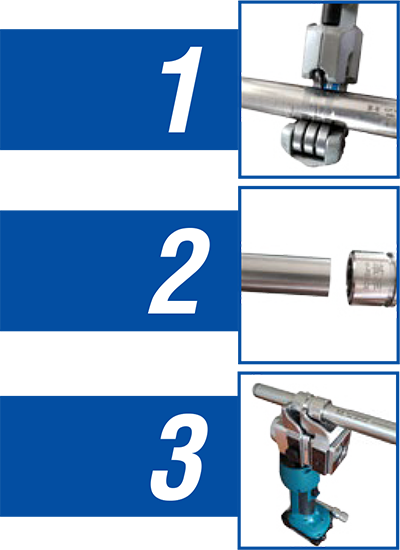

Cutting pipes

Cutting pipes

• Use metal pipe cutters

• No need for chamfering and deburring

• No "O" rings for fittings, no fear of cuts and leaks

Socket pipe fittings

• No special treatment is required, just clean, no debris cement, etc.

• Directly cut the pipe directly into the pipe fittings to the end

• The pipe fittings are elaborately made and do not loosen easily after insertion

Sliding pressure connection

• Put the tool on the connector that needs to be connected

• Buckle up and press the button for 2-3 seconds to connect

• Power tool: one full charge can be connected 200 times, the battery is 180V, and the full time is 30 minutes

Worry-free after use

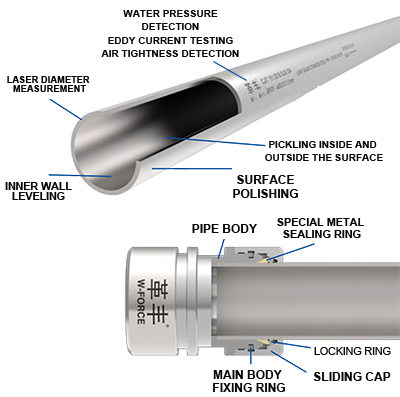

Leather abundance of stainless steel tubing special points:

Leather abundance of stainless steel tubing special points:

• surface finish • an inner wall screed

• cleaning / pickling • an eddy current testing

• Laser Diameter • pressure detecting

leather abundance of stainless steel sliding pressure seal fittings special points:

the tube body

S304 encapsulation materials

special metal ring

Replace the suspiciously unstable rubber sealing products. The

main body fixing ring

ensures the positioning of the pipe fittings. The

locking ring

ensures that the metal seal is in place. As the second layer of sealing function, the

sliding cap

covers the entire sliding pressure seal combination.